-Drawn by Jeff Smith

About:

About:

My most ambitious robot to date, one that can act on its own! Also, it wasnt enough to just build a robot, it needed to be full size!

I mean honestly, the bigger, the scarier. Anyways, The A.I is mostly being written in Visual Basic, and there are some interpretation algorythms

being utilized in Sentry, which is the visual software. The robot is made largely from car and computer parts, so yeah, completely from scratch.

The ultimate goal for this robot is to build it's entire body and to have it learn. I'd also like to use it as a test bed for developing how

computers and robotics interact with their environment using a method I'm developing called FetFar (Fully Encompassed Tactile Feedback

for Autonamous Robotics).

Now don't get me wrong, I realize the difficulties facing us when it comes to artificial intelligence, and I'm not even that great a programmer,

so I plan on starting off very simply. Once the arms are done, I just want it to lock on to a moving object, and if instructed, reach out and

grab it. Once that task has been attained (if ever), then I'd like to move on to object recognition.

Initial Prototyping and Testing:

Initial Prototyping and Testing:

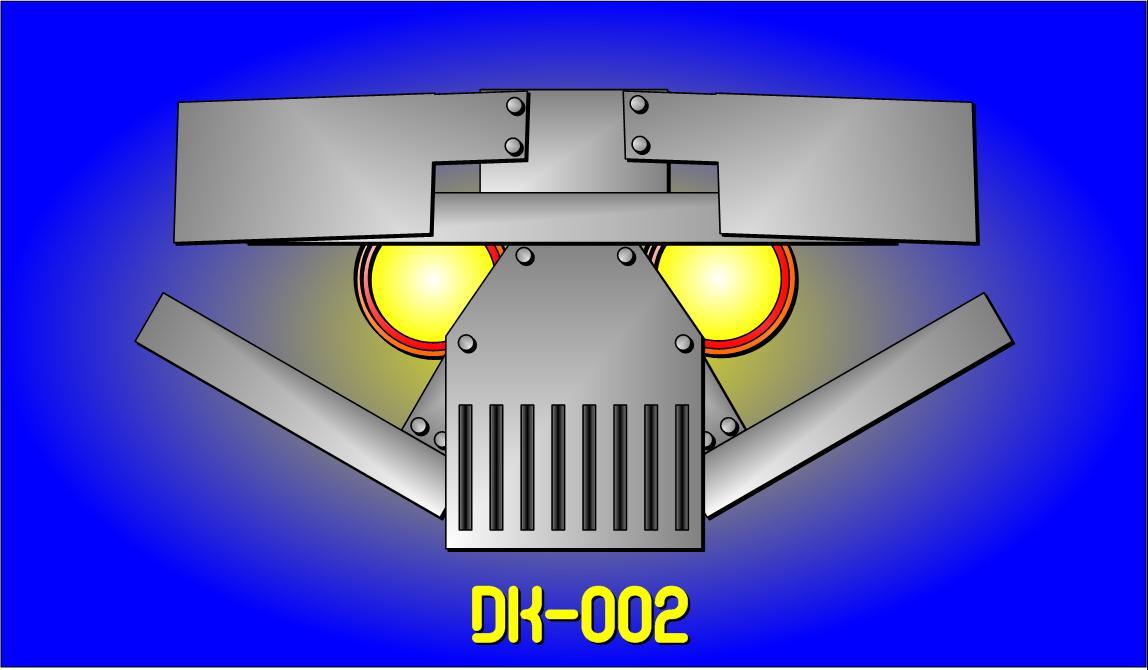

This contraption actually started off as just a proof of concept test. I wanted to see what was involved with trying to build a humanoid roboic

head. After a bunch of drilling, sawing, and pop riveting, I came up with this. I also wanted to see what physics were involved with giving it

a full range of natural motion (i.e. up, down, left, right). After the tests were complete, I thought it would make a nice photo subject, so I

put a bunch of LEDs on it, turned out the lights, and snapped away.

Neck and Head:

Neck and Head:

All by itself, the head weights about 15 pounds, so to raise and lower it takes a good bit of torqe. A power window motor still mounted to the regulator

from a ford taurus was the perfect solution. It operates on just 12 volts so a pc power supply can run it, since it uses a worm gear based revolution

reduction it has a high torqe action that can't be manually forced, and unlike most linear actuators, it's pretty quick. Directly, the motor raises

and lowers the upper neck platform which is what the head sits upon. The platform is stabilized by 2 sets of 1-inch pvc pipe which act as the ligaments.

Above the neck and on the platform, the head is attached with a 6-inch steel ball bering lazy susan. This provides the heavy head with ample stability

as it gets quite bulky as more and more sensors and instruments are attached. The x-axis movements are driven by a printer's carrage motor and a toothed

belt attached to either side of the head. The y-axis movments are driven by a car-seat motor which has an incredible amount of torque and is probably

overkill for this application but was necessary due to the inability to find a suitable alternative.

|

Local Relay Control Board:

Local Relay Control Board:

The relay controll board is the primary interface between the computer and the robot. It takes instructions from the computer's parallel port,

power from several sources ranging from standard wall adaptors to high-wattage pc power supplies, and provides the switching for all of the

robot's many motors. Remarkably, there is no processing done with-in this unit, only a small amount of combinational logic used to multiplex the

parallel data to the various memory locations (flip-flops). This allows the computer to drive many motors simulatneously even though the

communications link only allows for a fairly small bandwidth.

Input Module

Input Module

Since this robot is to learn, it is imperative to give the processors and software as much information about the world around it as possible.

This translates to inputs, and the more inputs the better. With the inputs you can attach all sorts of sensors; light, pressure, sound, etc.

This particular module gives me 32 discrete multiplexed data points and it plugs right into the local relay board for ease of implementation.

Anthropomorphic Arm 1 (6-1-09):

Anthropomorphic Arm 1 (6-1-09):

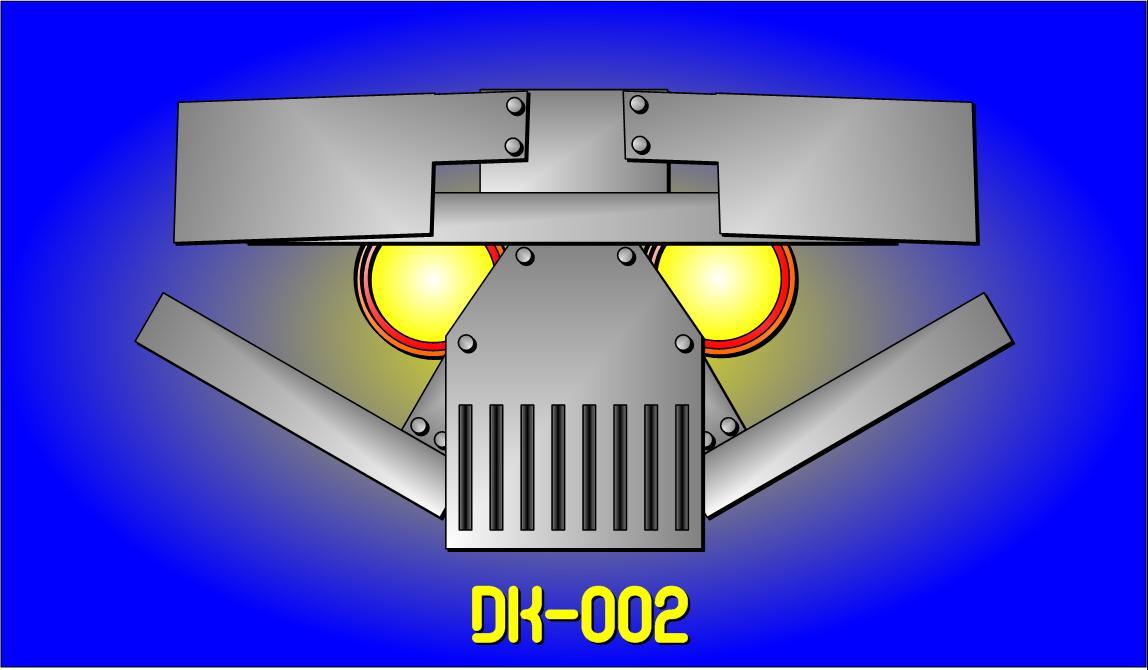

DK-002 finally gets a limb! It may be crude looking, but this contraption I'm calling an arm is actually classified as a

4.5 axis anthropomorphic articulated arm. It uses windshield wiper motors for the sholder and upper-arm, a power seat motor

for the fore-arm, a high torque server for the wrist, and a power drill for the robotic gripper. The arm it-self is actually

sort of a temporary addition as I really just needed something to attach to DK-002 so I could start tinkering with my object

locating and target aquisition algorithms. Really only the control circuits and gripper were intended for the long term.

Related Videos:

Related Videos:

About:

About:

Initial Prototyping and Testing:

Initial Prototyping and Testing:

Neck and Head:

Neck and Head:

Local Relay Control Board:

Local Relay Control Board:

Input Module

Input Module

Anthropomorphic Arm 1 (6-1-09):

Anthropomorphic Arm 1 (6-1-09):

Related Videos:

Related Videos:

Viewer Comments

Viewer Comments Leave A Comment

Leave A Comment